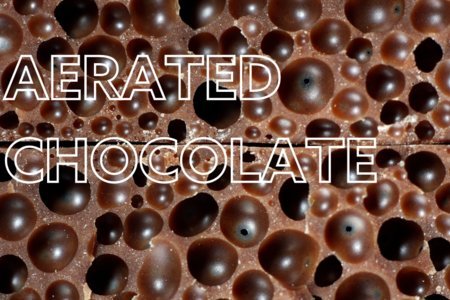

Aerated Chocolate

APPLICATION PURPOSE

To evaluate the feasibility of foaming pure chocolate with different fat content and fat components by means of MEGATRON® MT-MM in a controlled and gentle manner.

CHALLENGES

Foaming pure chocolate can be challenging due to the unique properties of this beloved product. Some of the challenges are the control of the temperature, the correct tempering, ensuring the desired texture and the controlled injection of the chosen gas.

HOW DID WE ACHIEVE IT?

Foamed chocolate, also called aerated chocolate, is a relatively new and innovative product that is gaining popularity among chocolate lovers worldwide. The texture of aerated chocolate is light due to the incorporation of gas during the manufacturing process which provides a totally different experience to the customer: the product becomes softer, creamier and smoother while it melts.

Some aerated chocolates and chocolate-like confectionary products are already out there in the market. Those are produced commonly by means of puffing under vacuum, inflating under high pressure1 and extrusion (including high-pressure extrusion).2 However, with the mentioned methods is difficult to control the amount of gas, bubble size and distribution which are important parameters not only to influence the melting behavior but also the flavor release.

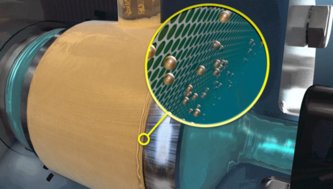

Innovative technologies are part of Kinematica’ s trademark, and the passion for innovation extends beyond its well-known rotor-stator systems to develop new technologies that exceed customer expectations. That’s how MEGATRON® MT-MM was born and it has been recently proven to contribute in the production of foamed pure chocolate overcoming the challenges it presents.

THE KINEMATICA SOLUTION

How can MEGATRON® MT-MM ensure a controlled inclusion of gas into chocolate? Well, it is a team-work in which a first tempering of the chocolate is followed by the foaming step. As in a regular chocolate, also for foamed chocolate tempering is key. Formation of fat crystals during chocolate tempering play vital roles in defining the structure, mechanical properties and appearance of chocolate and temperature is crucial to control this process.

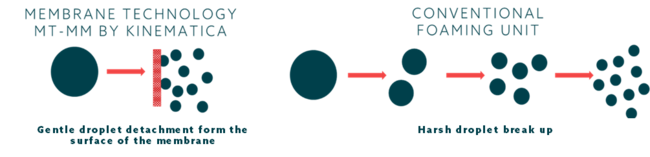

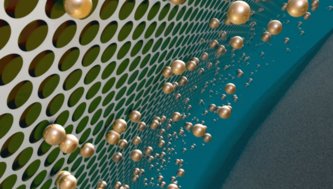

The characteristics of fat foams are dominated by the fat crystal network. Higher overrun and foamability are achieved due to the presence of higher melting fat crystals which provide enough structure to stabilize the N2 bubbles.3 Once the chocolate is properly tempered and the right fat crystals are ensured, the foaming takes place at the heart of MEGATRON® MT-MM, where the bubbles are already formed at the surface of a dynamically enhanced membrane and detached by the acting shear stresses to their final size which makes this process not only gentle but also controlled in bubble size and distribution.4

This foaming equipment has been proven to incorporate up to 50% N2 in a controlled manner not only in chocolate containing just cocoa butter as fat component but also in a milk chocolate with a mixture of cocoa butter and milk fat and in chocolate-like confectionary products.

See the comparison between 0% and 50% N2: The more gas is injected, the lighter the colour and the softer the texture.

Would you like to learn more? Please contact us at science@kinematica.ch.

1 Su-Jia, S., Dong, C., & Shi-Chao, X. (2013). The Foaming Abilities of Surfactants in Cocoa Butter: Cocoa Butter. Journal of Food Process Engineering, 36(4), 544–547. https://doi.org/10.1111/jfpe.12017

2 Koller, C. (2015). High-Pressure Micro-Foaming of Fat-Continuous Confectionery Systems [ETH Zurich]. https://doi.org/10.3929/ETHZ-A-010487068

3 Mishra, K. (2016). Foamability of confectionery related fat systems—The impact of fat crystal network [Institute of Food, Nutrition and Health Laboratory of Food Process Engineering]. ETH Zurich

4 Müller-Fischer, N. (2007). Dynamically enhanced membrane foaming [ETH Zurich]. https://doi.org/10.3929/ETHZ-A-005331832