ATOMIX® High Pressure Homogenizer

Kinematica presents the latest development on the high pressure market: ATOMIX® HPH. “The development resulted from many customer analyses and feedbacks. High-pressure homogenization is a technology with increasing market demand due to its efficient and widely applicable properties.”, postulates Head of Science, Lea Meier-Pokorny. High-pressure homogenization is ideal for nano-emulsification, sterilization processes or disruption of cells. It is used in various fields, such as pharma, food, cosmetics and biotechnology.

Nano-emulsions are widely demanded because of their improved stability and bioavailability when consumed.

ATOMIX - what is new?

Kinematica developed together with ETH in Zurich the new ATOMIX® HPH with ideal properties for the nutraceutical, cosmetic and pharma industry.

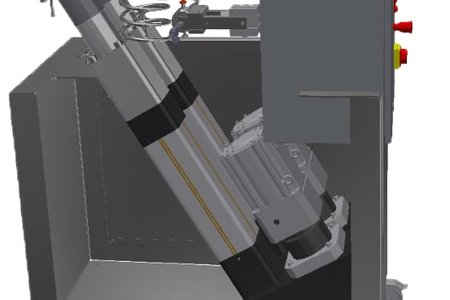

The optimized double piston pump works electromechanically, which makes it quiet and low in vibration. The phase-shift of the two pistons allows pulsation-free conveyance and results in minimal pressure loss. No puffer tank is required for the pressure balance.

The optimized design of the plunger is ideal for pharma application because of its possibility for cleaning and sterilisation in place (CIP and SIP).

A motor with high efficiency was chosen, so no motor cooling is needed and there is no turbulent air flow.

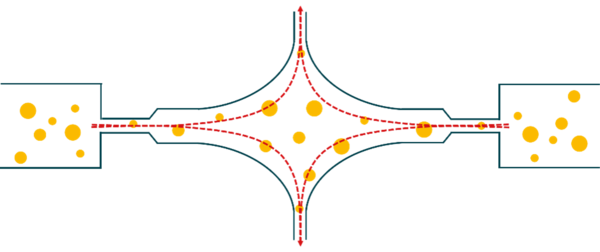

The newly designed working chamber is a counter-jet type of interaction chamber with radial diffuser, which reduces cavitation to a minimum for longer performance, reducing the investment costs. A controlled flow guidance leads to an improved product quality and minimal dead zones for an improved product quality and reduced number of cycles.

Illustration of new interaction chamber of ATOMIX® HPH of Kinematica (Source: Kinematica AG)

Smaller droplets, narrowly distributed

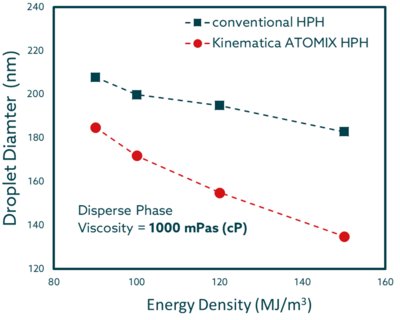

First tests at ETH showed very promising results and we are convinced that this new design will revolutionize the market.

The ATOMIX® HPH of Kinematica allows the formation of smallest droplets even at high viscosities. A dispersed phase viscosity of 1000 mPas results in 30% smaller droplets compared to the conventional HPH designs – or 30% less time and less energy required for the same result.

Not only the size is smaller, but also the size distribution is lower than the competitors' equipment. “When it comes to designing a new HPH, the resulting droplet size is important but even more important is the reduction in size distribution as it directly correlates with its stability.”, said David Gisler, designer at Kinematica.

With the new ATOMIX® HPH of Kinematica you get the full compliments of smaller droplets, narrow size distributions and highly stable emulsions in less time.

Encapsulation of iron or cannabinoid products

The goal of the project with ETH was the encapsulation of a new developed iron compound using the ATOMIX® HPH. The nano-emulsification of iron capsules increases the bioavailability and reduces iron insufficiency drastically. A simple O/W emulsion helped to improve the design of the interaction chamber to maximize the efficiency and can now be scaled to encapsulated systems.

The applications are not limited to emulsified materials, but also suspended products, such as, bacteria, algae and yeast cells. Results are still under development.

The cannabis market is increasing and with it the desire for nano-emulsified cannabinoid compounds, which are often difficult to handle because of their viscosity. The ATOMIX® HPH would be a great tool for such applications or other applications with similar handling challenges.

Trials for free

Kinematica would like to present with ATOMIX® HPH a new generation of high-pressure homogenizers for a more efficient processing and an improved product quality. We would like to get further inputs from industries to be able to improve ATOMIX® HPH. “We are looking for companies, that are interested in testing their products using the ATOMIX® HPH prototype, giving us feedback on performance and quality” says COO of Kinematica, Andreas Niens. “It is our vision to collaborate with companies for a steady improvement of our products.”

Please contact us under science@kinematica.ch for a free trial. Free trials phase ends 2021.